The past few years saw a big boom in the industry of LED grow lights industry worldwide, especially in growing herbs, a large number of different kinds of LED grow lights are in the application of grow, however, as different companies have different standards for their products, and almost all of them , more or less, hush up the inefficiencies in their quality assurance, sometimes, it gives a big loss to the distributors and growers, especially LED grow lights with COB technology, we are here to look into the quality of COB LED grow light, and provide you with professional insights for better knowledge of LED grow light, we herein mainly discuss the two main points that matter much to the quality assurance of COB LED grow light.

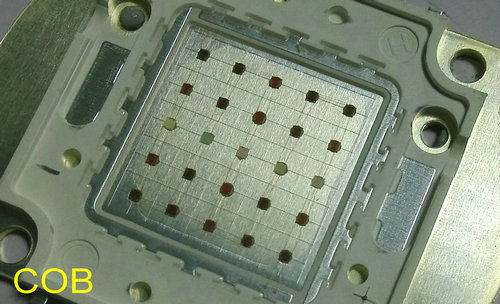

COB has proved to be the most effective grow light for plants because of its perfect light efficiency and color-mixing, there are usually a certain number of LED chips encapsulated on board, there are several factors which matters a lot to the quality assurance of COB:

We know that when LED chip is powered by a certain electric current, it will gives light, but only around 10% power energy is utilized as light, and 90% of power energy will be converted into heat, due to the special design of LED structure (base, gold wire, glue, frame, etc), an effective heat-sinking solution will at least accounts for 95% factor to the lifetime of LED grow light, below are the images of COB LED grow light with poor heat-sinking solution, causing big loss to growers.

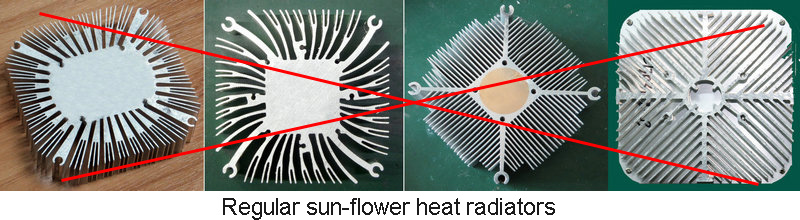

The heat-dissipater that the above defective COB LED grow light usually uses below common sun-flower heat-radiators with cooling fan behind, such radiators are actually not suitable for heat-sinking, as the temperature of COB is very high, the temperature of a COB with actual power wattage 100W will be as high as 300 degree! but the safe temperature of LEDs cannot be over 250degree, so that’s why a lot of COB LED grow light are apt to get incredible problems.

So what is the best heat-sinking solution for COB LED Grow light?

There is always a misunderstanding of temperature of LED grow light, almost all manufacturers declare that their temperature of grow light is only less than 45 degree, however, it is just the temperature of inside grow light, it has nothing to do the lifetime of LED grow light, what matters to the lifetime of grow light is the temperature of light source – COB, but many suppliers intentionally debarb this sensitive issue, as they did not realize what is the main reason that cause the failure of a COB LED grow light!

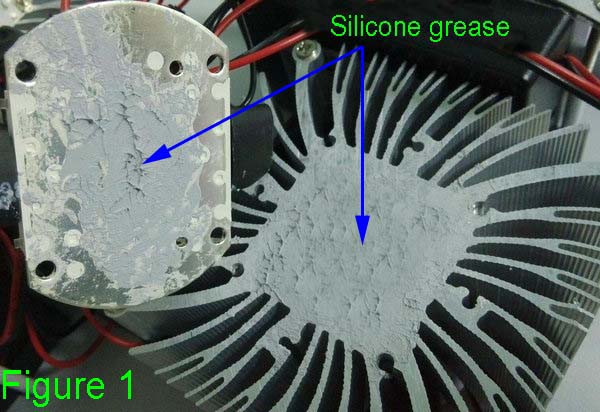

Let’s get in back to the point, firstly, to ensure the good heat-sinking of COB of LED grow light, we have to make the much heat created in the small area of COB give out very quickly, because the temperature of LEDs on COB is extremely high, it creates much heat every second, so the heat conduction is the first stage of heat-sinking, however, the above sun-flower heat-radiator just use silicone grease for heat-conduction of heat, although the heat conduction of good quality of silicone grease is able to reach 3.0, even 4.0 (Figure 1), but it cannot conduct the heat quickly to all areas of heat radiator, and the limit of heat-loading ability of aluminum heat radiator make it very slowly to dissipate the heat quickly, thus the temperature of core area of COB will always remain very high, leaving a high potential of breakdown.

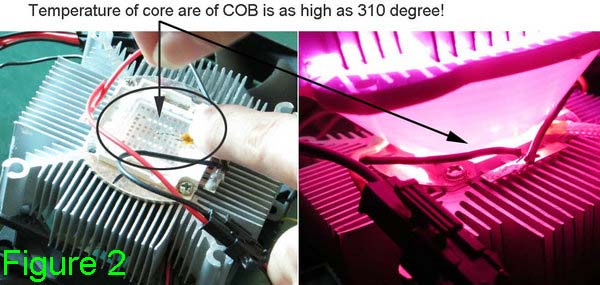

Below are the test of temperature of core are of 100W COB, Figure 2 is the test based on regular sun-flower heat radiator, we can see that it reaches over 310 degree!

Below is iMaster advanced thermal-tube heat radiator designed by iMaster Technologies, it is able to dissipate the heat very quickly to the aluminum fins, and the cooling fan will make is more effective to dissipate the heat while keeping the temperature of core area of COB remaining under 180 degree, which provides a solid guarantee to the lifetime of LED, gold wire and glue, etc.

What’s more benefits we get from thermal-tube heat radiator?

There are at least two important benefits from thermal-tube heat radiator:

Longer lifetime

It is obviously that, as the most important part of LED grow light, the lifetime of light source – COB – will be safely guaranteed, as the lifetime is a very basic standard for the reliability of product, and it is the main guarantee for your investment of return.

More yield

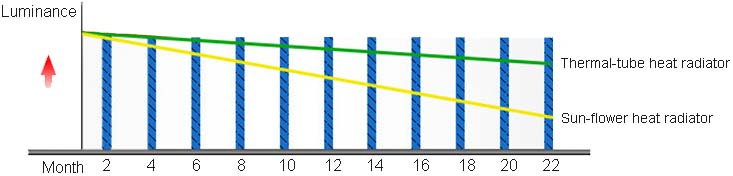

Thanks to the excellent heat-sinking solution, the LEDs on COB are always working in good condition, as the temperature of core area of COB is less than 200 degree, so the light attenuation of LED chip is also much more slowly than the COB on sun-flower heat radiator, as below test shows:

With the less light attenuation, the lifetime of COB will surely be largely extended, and the grow light will be able to provide more stable and higher quality light efficiency in different colors which matters much to the growth of plants.